A flange is a mechanical device, usually a flat - rimmed disc or collar.

· It's typically made of metal such as steel, stainless steel, or cast iron. A flange has holes around its perimeter. These holes are used to bolt the flange to another flange or a mating surface. For example, in a pipeline system, two flanges are bolted together to connect two sections of pipe.

· Connection: One of the main functions is to connect pipes, valves, pumps, and other equipment. In a large industrial plant, flanges are used to assemble a complex network of pipes that transport liquids or gases.

· Sealing: Flanges also provide a surface for gaskets. Gaskets are placed between two flanges to create a seal. This seal is crucial to prevent leakage of the substances being transported through the pipes. For example, in an oil refinery, the flange - gasket combination ensures that the crude oil doesn't leak out of the pipeline system.

· Support and Alignment: Flanges help in aligning and supporting the connected components. They ensure that the pipes and equipment are properly positioned and stable.

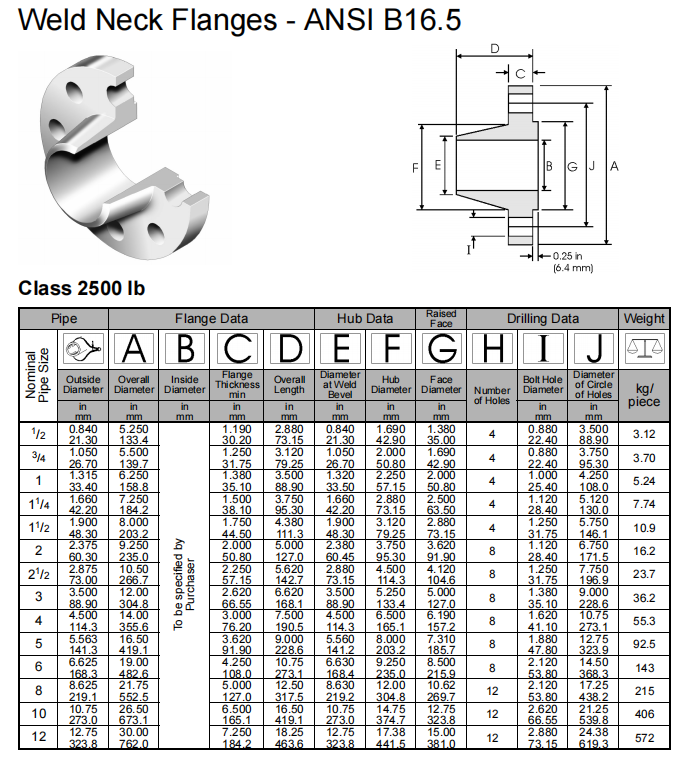

· Weld Neck Flange: This type is designed to provide high - strength connections. The long, tapered neck of the flange is welded to the pipe, and it can handle high pressures and temperatures. It's often used in high - pressure steam lines or in the chemical industry.

· Slip - On Flange: As the name suggests, it slips over the pipe end and is then welded both on the inside and outside of the flange - pipe junction. It's easier to install than a weld - neck flange and is commonly used in low - pressure applications such as water supply systems.

· Blind Flange: A blind flange is a solid disc used to close the end of a pipe or a flange opening. It's useful when a section of a pipeline needs to be temporarily or permanently sealed off, such as for maintenance or testing purposes.

Flanges are manufactured according to various standards. Here are some of the most common ones:

· ANSI B16.5: This is a widely used standard in the United States. It covers pipe flanges and flanged fittings for use in the oil, gas, and chemical industries. The standard includes specifications for flange dimensions, bolt sizes, and pressure - temperature ratings. For example, it defines the dimensions of a 2 - inch flange used in a refinery's piping system to ensure compatibility and safety.

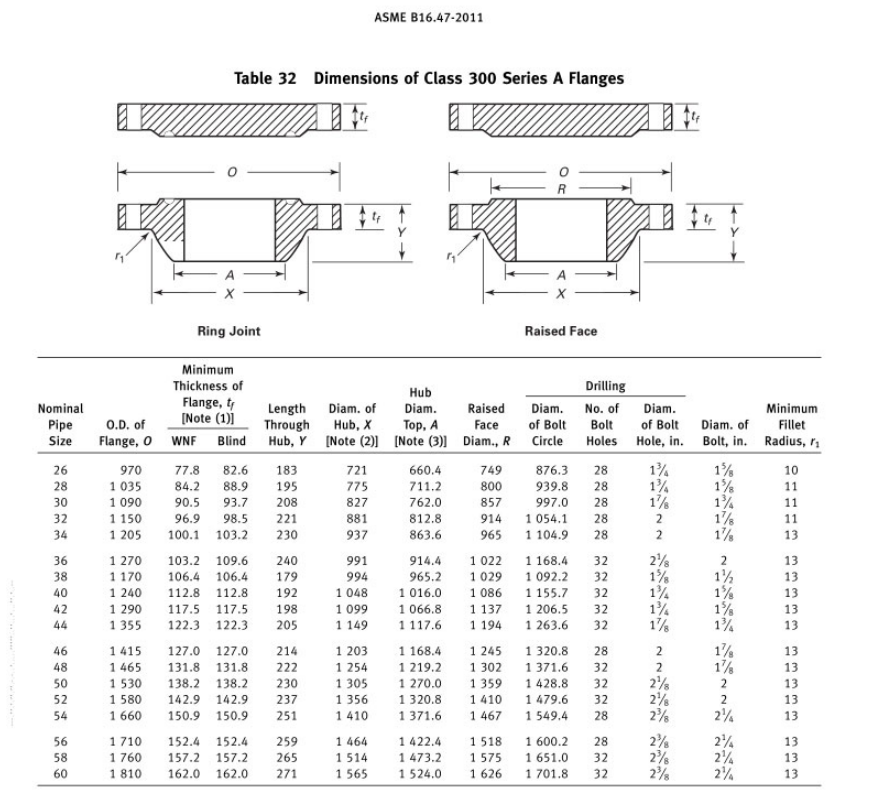

· ANSI B16.47: It's used for large - diameter flanges. These flanges are often required for pipelines that transport large volumes of fluids, such as in cross - country oil pipelines. The standard provides details for flanges with diameters ranging from 26 inches to 60 inches.

· DIN EN 1092 - 1: This European standard is used for circular flanges for pipes, valves, fittings, and accessories for use in industrial applications. It's similar to the ANSI standards in that it provides detailed dimensional and technical requirements. For example, in a European chemical plant, DIN - compliant flanges ensure that equipment from different manufacturers can be properly connected and operate safely.

· JIS B2220: It's the Japanese standard for steel pipe flanges. These standards are often used in Japanese - based industries and for equipment exported from Japan. They are designed to meet the specific requirements of the Japanese market, such as for precision - engineered piping systems in the electronics manufacturing industry.

· BS 4504: This standard provides specifications for flanges and their associated bolting and gaskets. It's used in the United Kingdom and in countries that follow British engineering traditions. In a UK - based water treatment plant, BS - compliant flanges ensure the reliable connection of pipes and equipment.

MESSAGE