Slip-on flanges connect two residential or commercial pipeline pipes. They come in variegated sizes and shapes. Hence, choosing the appropriate material is necessary to meet specific requirements.

The connecting method can be welding or bolting. It depends on personal preference and application needs. In short, slip-on flanges are a recommended choice for a secure pipe connection.

Pros:

1. Low cost

2. Easy installation and assembly

3. Occupy minimum longitudinal space for a flange.

4. Slip-on flanges come in a wide range of diameters.

Cons:

1. Not suitable for high-pressure applications

2. Not suitable for use with hazardous gases or fluids

Flange Standard: ASTM A182, ASTM A105, ASTM A234 WPB, A860,A694,AWWA C207

Flange Material: Carbon Steel Flange, Alloy Steel Flange, Stainless Steel Flange

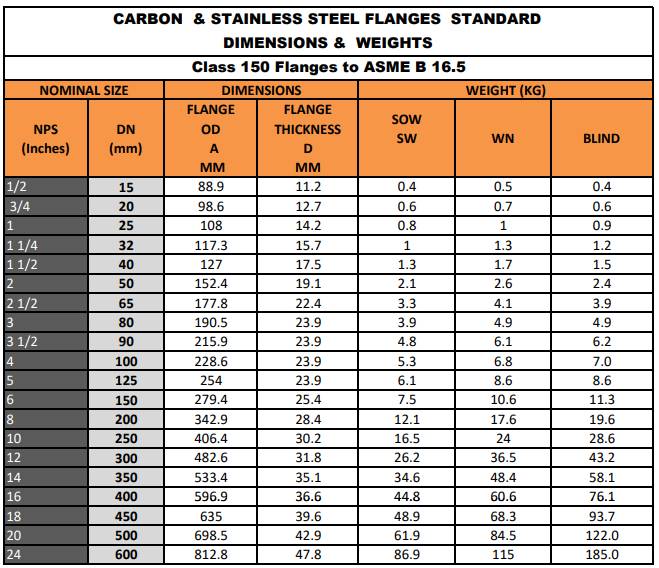

Flange Sizes: 1/2”-60” NPS (DN15-DN3000), SCH10,STD,SCH40,SCH60,XS,SCH80,SCH120,SCH160,XXS

Flange Class: Class150-Class2500

Flange Facing: RF/ FM/ M/ T G/ RF / FF / RTJ

Flange Types: Socket Weld Flange, Slip On Flange, Blind,Screwed Flange, Ring Joint Flange, Weld Neck Flange, Long Weld Neck Flange

MESSAGE