3 PE coating steel pipe can be also used in urban fuel gas piping system, storage tanks and groove piping system, protecting pipe in electricity and communication industries and water piping systems.

3PE anti-corrosion pipe three-tier structure:

The first layer of epoxy powder (FBE> 100um), the second adhesive (AD) 170-250um, the third layer of polyethylene (PE) 2.5-3.7mm.

Three of the integration, and steel pipe with a good solid coating. Diameter of Φ159-Φ1220.

2PE pipe anti-corrosion two-story structure, the first layer adhesive (AD), the second layer of polyethylene (PE), two kinds of integration.

Coating Material: Epoxy Powder, Adhesion, Polyethylene Or Polypropylene, Cement Inside

3PE anti-corrosion consists of three layers of structure:

The first layer of epoxy powder is greater than 100Um

The second layer of adhesive, (AD) 170-250um.

The third layer of polyethylene (PE) 1.8-3.7mm.

2PE anti-corrosion (two-layer polyethylene) structure:

The first layer of adhesive, (AD) 170-250um.

The second layer of polyethylene (PE) 1.8-3.7mm

3PE Coating Steel Pipe/2PE Coating Steel Pipe:

Coating Material: Epoxy Powder, Adhesion, Polyethylene Or Polypropylene, Cement Inside

Standard: API 5L (PSL1, PSL2); GB/T 9711.1;

Grade: Gr. B, X42, X46, X52, X60, X65, X70, X80; Gr. C;

The third party, SGS, BV, can be accepted.

2PP PRESERVATION:

PP anti-corrosion pipe two-story structure: the first layer adhesive (AD), the second layer of polypropylene (PP), two kinds of integration, three layers thick with the same PP.

3PP PRESERVATION:

PP three-tier structure of anti-corrosion pipeline:

The first layer of epoxy powder (FBE50 – 100um),

The second adhesive (AD) 250 – 400um,

The third layer of polypropylene (PP) 1.4 – 4.0mm.

Three of the integration, and steel pipe with a good solid coating, Coating temperature up to 110 degrees.

Diameter of Φ159 – Φ1440

Specifications:

THICKNESS OF 3LPE COATING ON STEEL PIPES

Minimum 125 µm Epoxy layer thickness

Minimum 150 µm copolymer layer thickness

Minimum thickness of 1.8 mm to 4.7 mm polyethylene or polypropylene layer

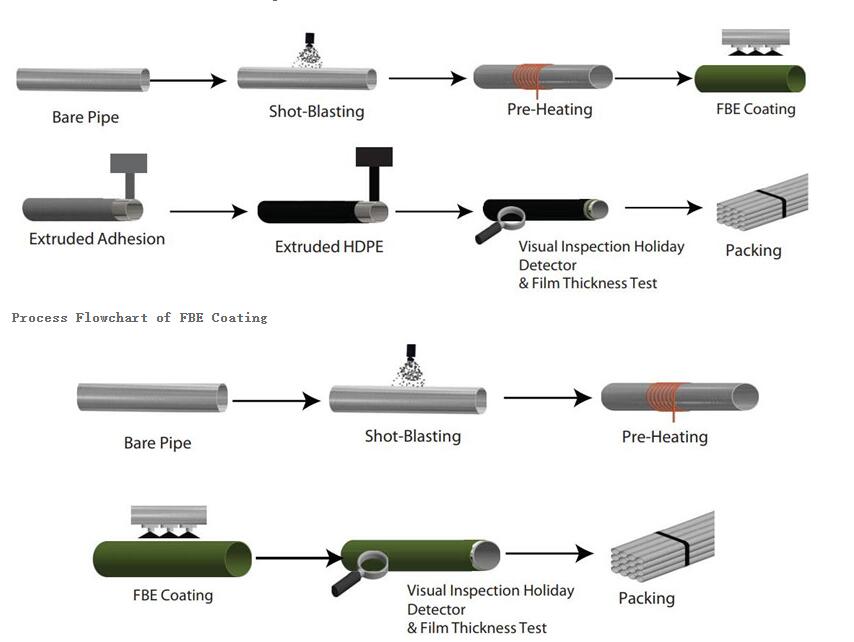

Production process:

Packing:

| Minimum total layer thickness range | |||||||||

| M kg/m | Layer thickness in mm | ||||||||

| Class A1 | Class A2 | Class A3 | Class B1 | Class B2 | Class B3 | Class C1 | Class C2 | Class C3 | |

| M ≤ 15 | 1,8 | 2,1 | 2,6 | 1,3 | 1,8 | 2,3 | 1,3 | 1,7 | 2,1 |

| 15 < M ≤ 50 | 2,0 | 2,4 | 3,0 | 1,5 | 2,1 | 2,7 | 1,5 | 1,9 | 2,4 |

| 50 < M ≤ 130 | 2,4 | 2,8 | 3,5 | 1,8 | 2,5 | 3,1 | 1,8 | 2,3 | 2,8 |

| 130 < M ≤ 300 | 2,6 | 3,2 | 3,9 | 2,2 | 2,8 | 3,5 | 2,2 | 2,5 | 3,2 |

| 300 < M | 3,2 | 3,8 | 4,7 | 2,5 | 3,3 | 4,2 | 2,5 | 3,0 | 3,8 |

| Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. | |||||||||

| Class 1 and 2 for medium and light applications (sandy soil). | |||||||||

| Class 3 – application in extreme conditions (rocky soil) or underwater. |

| Minimum thickness of finished coating | |||||||||

| Pipe Sizes (Specified OD) | Minimum Coating Thickness Chart (mm) | ||||||||

| ≤ 10 3 /4” (273.1 mm) | 2.5 | ||||||||

| > 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) | 2.8 | ||||||||

| > 20" (508.0 mm) to ≤ 30" (762 mm) | 3 | ||||||||

| > 32" (813.0 mm) | 3.3 | ||||||||

| External Coating | |

| Coating Type | Coating Standard |

| Single Layer FBE | SY/T 0315-2005, CAN/CSA Z245.20-2010, |

| DEP 31.40.30.32-Gen-2011, ISO 21809-2-2007, API RP 5L9-2001 | |

| Double Layer FBE | Q/enPC 38-2002, CAN/CSA Z245.20-2010 |

| 2LPE/2LPP Coating | SY/T 0413-2002, GB/T 23257-2009, ISO 21809-1-2009 |

| 3LPE/3LPP Coating | SY/T 0413-2002, GB/T 23257-2009, DIN 30670-1991, CAN/CSA Z245.21-2010 |

| ISO 21809-1-2009, NF A49-711-1992, NF A49-710-1988 | |

| Concrete Weight Coating | Q/HS 3017—2008 |

| Insulation Coating | SY/T 0415-1996, CJ/T 114-2000, EN 253-1994 |

| Bitumen Coating | BS 534-1990 |

| Internal Coating | |

| Coating Type | Coating Standard |

| Internal Liquid Epoxy Coating | API RP 5L2-2002, DEP 31.40.30.35-Gen-2005 |

| Single Layer FBE | API RP 5L7-1988 |

| Internal Cement Lining | BS 534-1990, AWWA C205-2000 |

| Bitumen Coating | BS 534-1990 |

MESSAGE