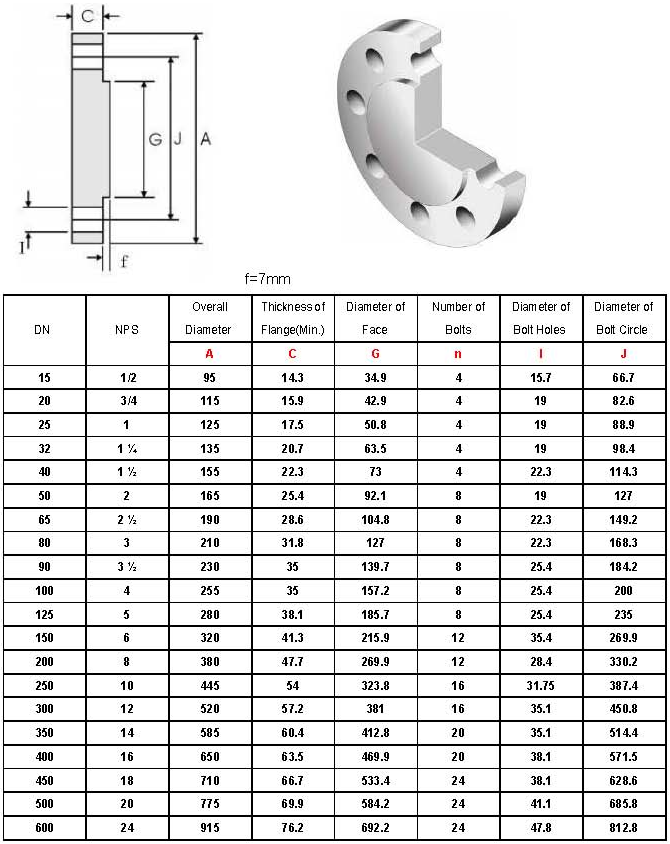

Diamention of Blind Flange - ASME B16.5 Class 400

Generally has four types: Forging, casting and forging, medium plate cutting, casting

Price(From expensive to cheap):

1. forging products

2. the middle plate

3. casting and forging

Blind Flange material usually required in carbon steel, stainless steel, alloy steel, copper, aluminum and etc.

Carbon steel blind flange: ASTM A105

Alloy steel: ASTM A182 F5, F9, F11, F22, F91

Stainless steel blind flange: ASTM A182 F304/L, F316/L

Sizes: 1/2'' to 24'', Customized up to 48''

Thickness: Schedule 10(S) to SCH 160

Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500

Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Pressure Ratings: Class 150 to 2500

MESSAGE