Stainless Steel Fittings are used to join two or more lengths of pipe or to close off the end of a pipe. SS tees are designed to allow a line to be split into two lines with a connection that is at a 90-degree angle. It can also be used to connect two lines into one main line when mixing chemicals.

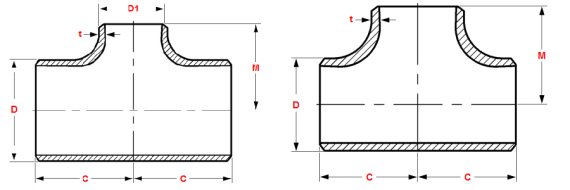

The two terms used to describe the pipe and its perpendicular connection are header and branch. The main run of pipe is called the header, whereas the perpendicular line that connects to the header is known as a branch. On a straight tee, all three outlets are of the same nominal pipe size. A reducing tee has a branch that has a smaller line size than the header. Since all pipelines 12” and smaller are drawn single-line, and therefore, the pipe diameters are difficult to distinguish, a branch that is 12” and smaller must be identified with a note that defines the header size and the branch size. Notice the weld tee requires three welds be made to install the fitting within the header. Pay particular attention to the weld dot used to represent the weld on the 12″ and smaller branch outlet on the reducing tee.

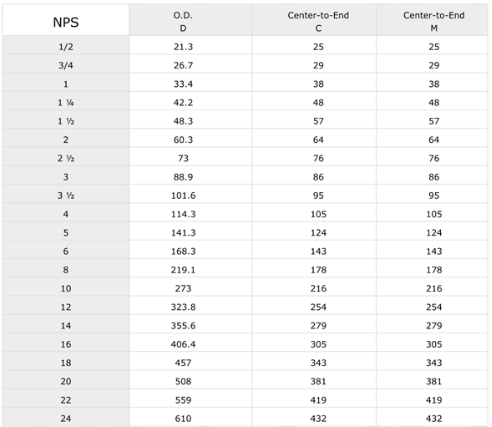

Before drawing the weld tee, two dimensions must be determined. The first dimension is required to establish the center-to-end length of the header portion of the tee and the second dimension is used to establish the length of the branch portion of the tee. If a straight tee is to be drawn, use the Welded Fittings–Flanges Dimensioning Chart to find the C dimension of the tee. The C dimension is the center-to-end measurement for both the header and branch lengths. Therefore, the C dimension must be doubled to find the total length (end-to-end) of the fitting.

Standard Carbon Steel Weld Tee

Seamless Butt Weld Fittings conform to ASTM A/SA234 WPB through 24”

Weld Fitting Dimensions conform to ANSI B16.9, B16.11, B16.28 through 24”

Weld Fitting Dimensions larger than 24” conform to MSS-SP-48

Carbon content not to exceed .25% maximum

Manufacturing Facilities are ISO Certified

Mill Test Reports available with every order.

MESSAGE