IPN8710 anti-corrosion is applicable when there are many types of corrosive media inside the steel pipe. The IPN8710 anti-corrosion primer is composed of polyurethane polyethylene, modified epoxy resin, non-toxic anti-rust pigments and fillers, additives, etc., and is used for the anti-corrosion priming coating on the inner wall of the water supply pipeline; The IPN8710 anti-corrosion topcoat is modified by epoxy and rubber resin, and composed of non-toxic anti-rust pigments and fillers, additives, etc., and is used for the anti-corrosion topcoat on the inner wall of the water supply pipeline.

Steel surface treatment is mainly anti rust, the following is anti rust process:

First step is to clean, use cleaning solvent emulsion cleaning the steel surface, in order to achieve the removal of oil, grease, dust, lubricants and similar organic matter, but it can not remove the steel surface rust, oxide, solder medicine.

Second step is to right tools rust, rust tools you want to have to use a wire brush, wire brush to remove loose or warped oxide, rust and slag. To achieve the desired effect of the rust, the hardness of the steel surface must be based on the original extent of corrosion and the required surface roughness, coating, etc. to select the type of abrasive, the epoxy layer, two or three layers polyethylene coating, using mixed abrasive grit and steel shot blasting easier to achieve the desired effect.

Third step is to do pickling, chemical and electrolytic pickling generally use two methods, using only chemical pickling pipeline corrosion. Although chemical cleaning can achieve a certain surface cleanliness and roughness, but there are some pollution to the environment.

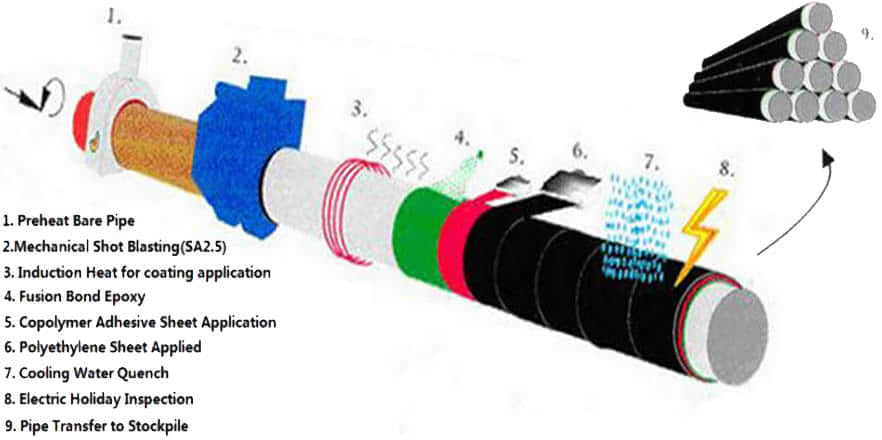

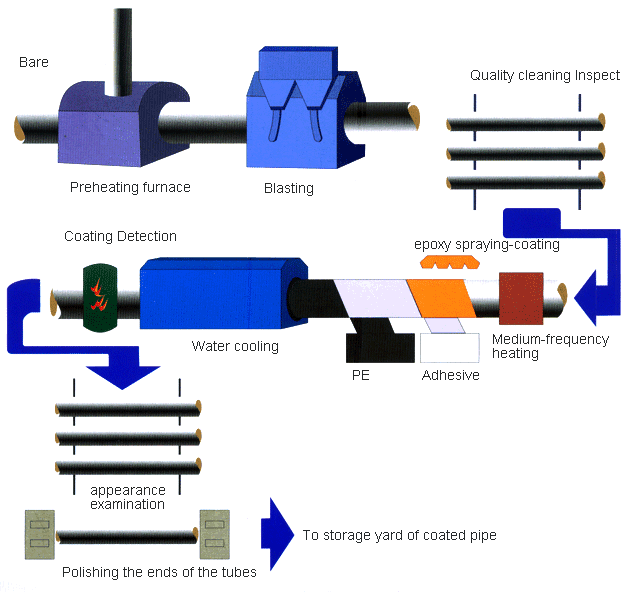

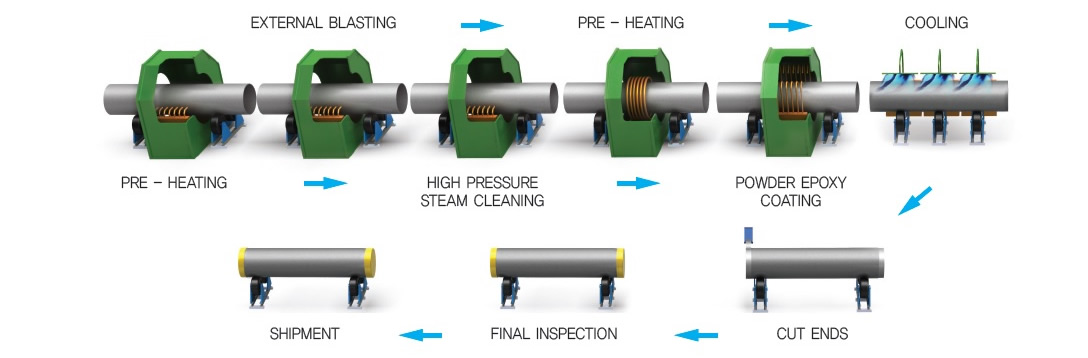

Process Diagram of Three-Layer PE PP Coating:

Finally emphasis on the importance of surface treatment in the production, strictly control the process parameters when anti rust.

| Product Name | IPN8710 Drinking Water Steel Pipe |

| Out Diameter | 219Mm-3048Mm, 8"-120" |

| Wall Thickness | 4Mm-30Mm, SCH 5S, SCH 10S, SC Large Diameter SSAW Steel Pipe For Fluid Service H10, SCH20, SCH30, SCH40S, STD, SCH40,SCH60, SCH80S, XS, |

| SCH80, SCH100, SCH120, SCH140, SCH160, XXS,Etc. | |

| Length | 6M-32M |

| Standard | API 5L, ASTM A252, EN10219, EN10217, ISO3183, GB/T9711, SY/T5037, SY/T5040, Etc. |

| Material/Steel Grade | A, B, X42, X46, X52, X56, X60, X65, X70,L210, L245, L290, L320, L360, L390, L415, L450, L485, |

| BN, X42N, X46N, X52N, X56N, X60N,BM, X42M, X46M, X52M, X56M, X60M, X65M, X70M, | |

| X80M, X90M, X100M, L245R, L290R, L245N, L290N, L320N, L360N, L390N, L415N,L245M, L | |

| 290M, L320M, L360M,L390M, L415M, L450M, L485M, L555M, L625M, L690M,Grade 1, | |

| Grade 2, Grade 3, St33, St37, St42, St34-2, St37-2, St42-2, St52-3, P195, P235, P265,S355NH, | |

| S355NLH, S460NH,S460NLH, S275MH, S275MLH, S355MH, S355MLH,S420MH, S420MLH, | |

| S460MH, S460MLH, Q195, Q215, Q235, Q345, Etc. | |

| Certificate | EN10217, EN10219, API 5L PSL1/ PSL2, ASTM A252, KS 4602, KS3583, GB/T9711.1/2,Etc. |

| End | Plain End, Spigot & Socket Joint, Beveled, Cut Square, Flanged, Piling Shoes,Etc. |

| Surface | Bare, Varnished, Black Lacquer, Bitumen Coating, Zinc Coating, Anti-Corrosion Coating, 3PE, |

| FBE,Epoxy, Cement Mortar, As Per Customer’S Requirement; | |

| Hydrostatic Test Range | Max Length 21 Meters; Max Diameter 2600Mm; |

| Test | Chemical Component Analysis, Mechanical Properties (Ultimate Tensile Strength, Yield Strength, Elongation),Metallographic Test, Technical Properties (Bending Test, Charpy-V Impact Test, |

| Hydrostatic Test, X-Ray Test, Ultrasonic Test) | |

| Packing | Usually In Loose Pieces; Can Be Packed As Customers’ Special Requirements |

| Application | - Line Pipe For Use In Pipeline Transportation Systems In The Petroleum And Natural Gas Industries; |

| - Applies To Pipe Piles In Which The Steel Cylinder Acts As A Permanent Load-Carrying Member, Or As A Shell To Form Cast-In-Place Concrete Piles; | |

| - Predominantly Used In The Construction Of Chemical Plant, Vessels, Pipe Work And For General Mechanical Engineering Purposes; | |

| - Applies To Structural Hollow Sections And Pressure Purposes Etc. |

MESSAGE