Face Type: RF, RTJ

-RF socket weld flange has a small portion surrounding the flange bore that protrudes from the face. Gasket seat will be placed in this raised area.

-RTJ socket weld flange has a groove on the raised face surface, you can place a gasket ring to get better sealing performances.

Pros:

1. Could replace threaded flange to minimize the risk of leakage.

2. No need for beveling before welding.

3. Welding is done outside the pipe and will not penetrate the pipe bore.

4. It is recommended for applications where internal welding operations are particularly difficult.

5. This socket welded construction eliminates internal pockets while avoiding warpage from welding heat and damage to the flange face caused by weld spatter.

6. It has the same internal pressure as the sliding flange and has a better fatigue life.

Cons:

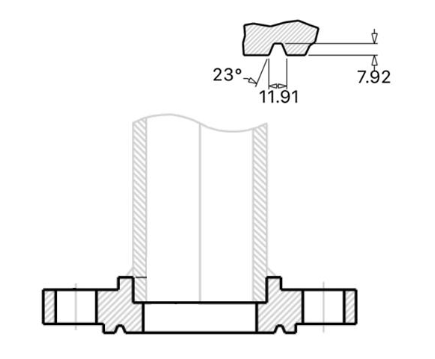

1. Socket welded flange requires higher skills for the welder, and the welding needs to ensure that the expanding gap between the pipe and the shoulder is 1/16 inch.

2. The expansion gap creates the chance for crack defects, especially for anti-corrosive pipes like stainless steel pipes. So, the cracks between the pipe and the flange will cause corrosive problems. Thus, SW flange is not compatible with corrosive or radioactive environments, as this solid buildup at the joint can cause operational and maintenance problems.

3. That's why people use butt welding more often as the welding completely penetrates the pipe from outside to inside, which makes the connection stronger and anti-corrosive.

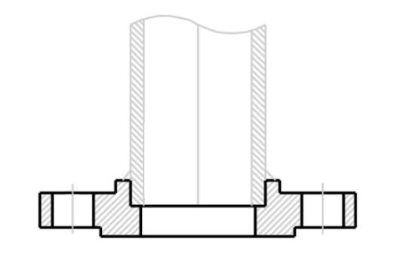

4. The shape of socket weld flange is similar to slip on flange, but differently it has a shoulder at the inner bore.

5. Slip on flange - No shoulder at the inner bore.

6. The static strength of socket weld flange is equal to slip on flange, but its fatigue strength is 50% higher than the double welded slip on flange.

Common Standard Materials:

Carbon steel: ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel: ASTM A182 F5, F9, F11, F22, F91

Stainless steel: ASTM A182 F304/L, F316/L

Size and Type:

Stocked in sizes from 1/2" to 6"

Outer Diameters: 1/2 inch to 24 inch, up to 2500#

Special made: 24'' to 60'', up to 900#

Wall Thickness: Schedule 40 to 160

Pressure Ratings: Class 150 to Class 2500

MESSAGE