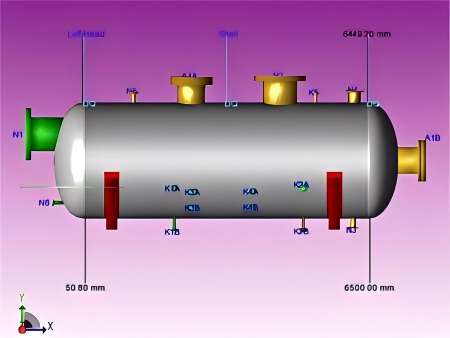

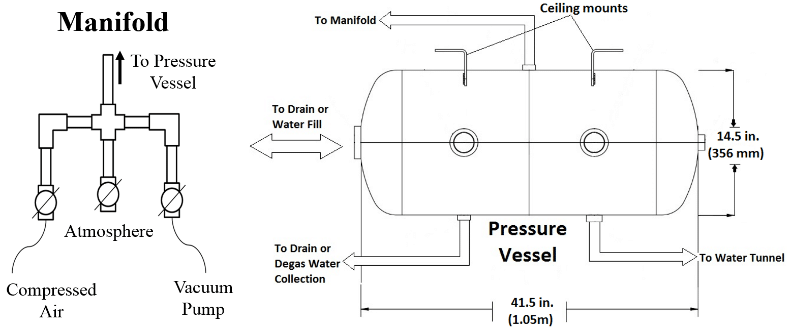

GAS-COLLECTING PIPELINE, we also called in GAS PIPELINE HEADER OR PRESURE VESSELS, is a device used to connect and aggregate multiple gas pipelines, which is commonly found in natural gas, petroleum, chemical and other industries.

We specialize in providing top-quality pressure vessel fabrication services tailored to meet the specific needs of our clients. Our process begins with thorough consultations to understand the unique requirements of your project, ensuring that we deliver a solution that perfectly fits your application. Utilizing advanced techniques and high-quality materials, our skilled fabricators meticulously craft pressure vessels with precision and reliability. Throughout the fabrication process, we maintain strict adherence to industry standards and regulations, guaranteeing that the final product meets all safety and quality requirements.

Its main function is to collect gases from multiple gas pipelines into a main pipeline for transportation, distribution and use. The Gas-collection pipeline, is usually composed of steel pipes, flanges, seals, etc. Its structural forms are diverse and can be customized according to different use environments and requirements. When selecting Gas-collection pipeline, it is necessary to consider factors such as the nature, flow, pressure, temperature of the gas, as well as the layout and installation requirements of the pipeline system.

When installing and using Gas-collection pipeline, it is necessary to follow relevant standards and specifications to ensure correct installation, reliable sealing, and safety and reliability.

At the same time, regular maintenance and inspection are also required to promptly discover and deal with possible problems to ensure the normal operation and service life of the gas manifold.

In short, the gas manifold is an important component of the gas pipeline system, and its correct selection and use are of great significance to ensure the safe operation and service life of the pipeline system.

We can design GAS-COLLECTING PIPELINE Up to 8 MTR Dia. X 40 MTR Long

Up to 10’ outside diameter

Stamped vessels and chambers

Automated welding

Weld cladding

Stainless and carbon steel

Jacketed chambers and doors

Painted and primed in-house

Engineered in-house or to print

Explosion clad materials

ASME Pressure Vessel Features

We offer extensive expertise in the mechanical design of ASME pressure vessels that will meet rigorous quality standards and procedures and are guaranteed for a long, trouble-free vessel life. Additionally, we have designed and built components and vessels conforming to ASME B31 and various API specifications. This allows Alloy Engineering to fabricate utilizing a wide variety of materials that spans several industries.

MESSAGE