Polyethylene thermal insulation steel pipe is a kind of lightweight, high-strength, corrosion-resistant non-metallic pipe. It is a glass fiber with resin matrix weight that is wound on a rotating mandrel layer by layer according to the process requirements, and quartz sand is evenly spread between the fibers as a sand layer. Its tube wall structure is reasonable and advanced, which can give full play to the role of materials. Under the premise of meeting the strength of use, it improves the rigidity and ensures the stability and reliability of the product. Glass fiber reinforced plastic sand is accepted by the majority of users due to its excellent chemical corrosion resistance, light weight and high strength, no scaling, strong shock resistance, long service life compared with ordinary steel pipes, low comprehensive cost, fast installation, and reliability.

Performance characteristics of high-density polyethylene thermal insulation steel pipe:

1. Rigid polyurethane with low thermal conductivity and good thermal insulation performance is used as the thermal insulation material, which has excellent thermal insulation properties.

2. When the water at 130℃ is transported to a distance of 40 kilometers after normal operation, the temperature drop is only about 1℃.

3. It has strong waterproof and corrosion resistance, no need for additional pipe trenches, and can be directly buried in the ground or water. The construction is simple and fast, and the overall cost is low.

4. It also has good corrosion resistance and impact resistance under low temperature conditions, and can be directly buried in the permafrost layer.

5. The high-density polyethylene thermal insulation steel pipe uses a corrosion-resistant (HDPE: high-density polyethylene) outer casing, which is not affected by biological and chemical corrosion.

6. High-density polyethylene thermal insulation steel pipes can be provided with various pipe diameters and thermal insulation thicknesses between DN20 and DN1200 and matching pipe fittings (elbow, tee, reducer, fixed joint, etc.) according to user needs.

7. The product implements the industry standard of urban construction.

8. In order to ensure the three-dimensional high-density polyethylene thermal insulation steel pipe, the outer surface of the steel pipe is shot blasted before foaming, the inner surface of the plastic pipe is corona treated, and the rust removal and so on meet the requirements, and the inner surface tension of the outer shell pipe reaches 50 dynes/cm.

9. The high-density polyethylene thermal insulation steel pipe is made of high-density polyethylene material, supplemented by various additives such as antioxidants, and the quality of raw materials and products is strictly inspected to ensure that the product quality meets the CJ/114-2000 standard and direct The technical requirements for the outer protection pipe of the buried pipe improve the overall quality of the outer protection pipe. The specific technical indicators are shown in the table below.

10. The company is equipped with imported and domestic high-pressure foaming machines and hydraulic pipe threading machines, which improves the overall quality of the products.

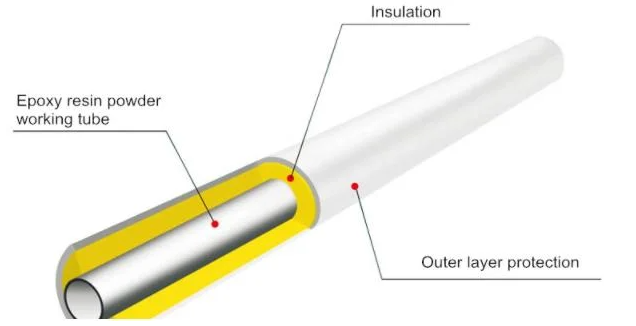

A pre-insulated pipe normally consists of three parts

Part 1: Carrier pipe (Inside): Stainless steel or Carbon steel

Part 2: Insulating layer (Medium): Polyurethane foam (PUR Form) (High insulation qualities compared to mass and volume)

Part 3: Protective jacket (Outside casing): Plastic or steel (Polyethylene (PEH), High Density Polyethylene (HDPE), Galvanized, Aluminum etc)

Pos: The choice of carrier pipe, foam type and foam thickness, as well as the material for the jacket, is made by the customer, who can also choose to supply carrier pipes for the project.

Advantages: impact-proof, watertight, resistant to salt and chemicals, hygienic and non-corrosive

| Description | polyurethane thermal insulation steel pipe | |

| Wall thickness | 0.5mm-16mm | |

| Length | 1m-12m or customized | |

| Outer Diameter | 0.405-80 inch or 10.3mm - 2032mm | |

| Insulation | PUR Foam | |

| Operating temperature | Up to 140ºC | |

| Standard & Grades | API 5L PSL1/ PSL2, ASTM A53,ASTM A252,GB/T9711.1,GB/T3091,SY/T 5037-2012,DIN1626,EN10219,EN10217 | |

| Ends | 30~35° | |

| Quality control | 100% X-Ray inspection/ 100%X | |

| 100% Hydraulic Pressure test/ 100% | ||

| 100% Ultrasonic inspection / 100% | ||

| Lining | Epoxy , cement motar, and according to customers requirement | |

| Operating pressure | <1.6Mpa (Equivalent to PN 25? 25bar to be confirmed) | |

| Laid way | Buried, overhead, trench | |

| Insulation material | Fluoride-Free water foamed rigid polyurethane foam material | |

| (foam density: 60kg/m3-80kg/m³) | ||

| Inner surface tension of the high density polyethylene pipe | ≥50dy/cm | |

| Materials | ||

| Item | Material | Notes |

| Service pipe/Carrier pipe | Steel Pipe | API 5L PSL-1: GR.B X42, X46, X52, X60, X70 |

| API 5L PLS-2: ISO3183-L245, L290, L320, L360, L415, L485 | ||

| Insulation | Polyurethane foam (PUR) Nominal Density of 60¹+15-15 kg/m³ | Compressive Strength: ≥ 0.300 Mpa |

| Thermal Conductivity: ≤ 0.029 W/m·K@50ºC | ||

| Closed Cell Content: ≥90% | ||

| Water Absorption:<5% | ||

| Insulation Jacket | High-density polyethylene (HDPE) | As technical parameter |

MESSAGE