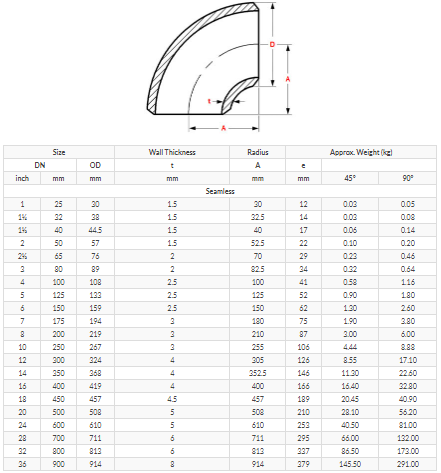

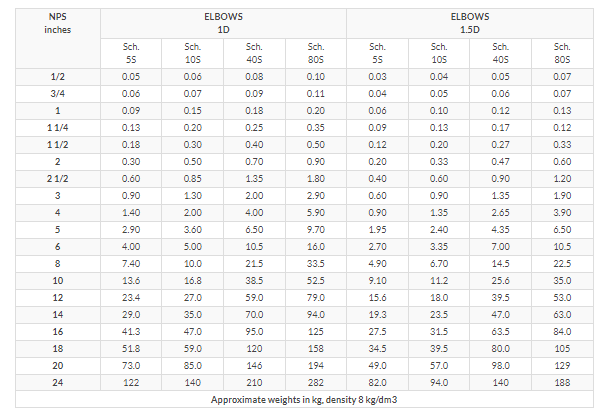

ASME B16.9 1D PIPE BEND DIMENSIONS, 1.5D PIPE BEND DIMENSIONS

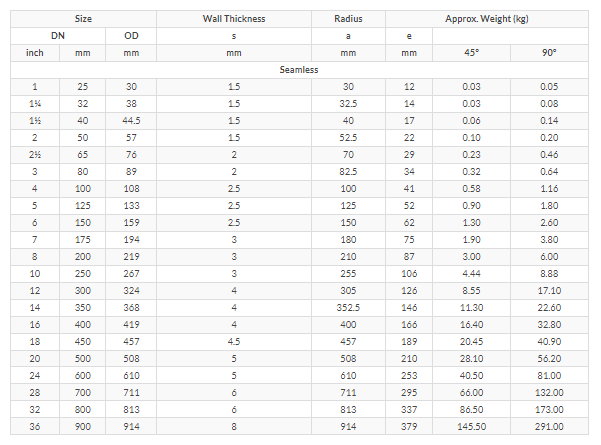

LONG RADIUS 1.5D PIPE BEND DIMENSIONS

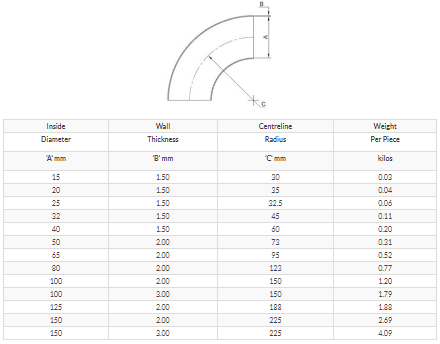

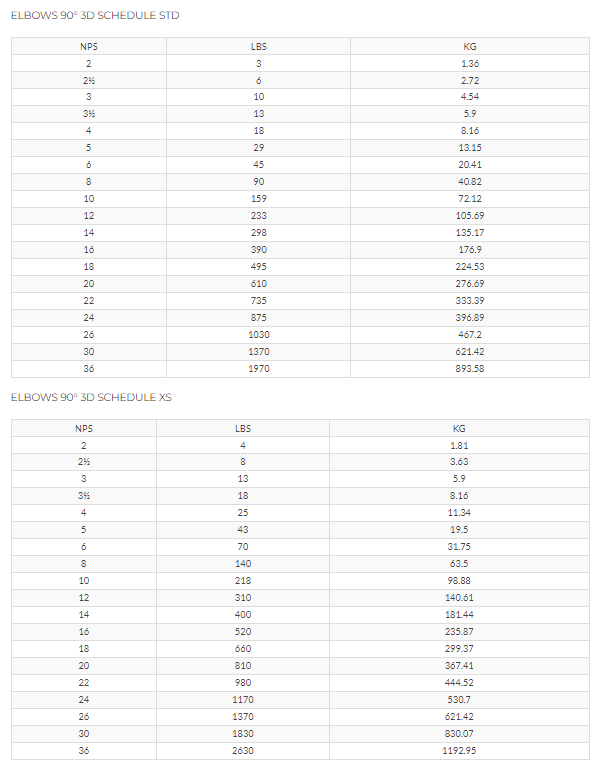

ASME B16.9 3D PIPE BEND DIMENSIONS, ANSI B16.9 3D PIPE BEND DIMENSIONS

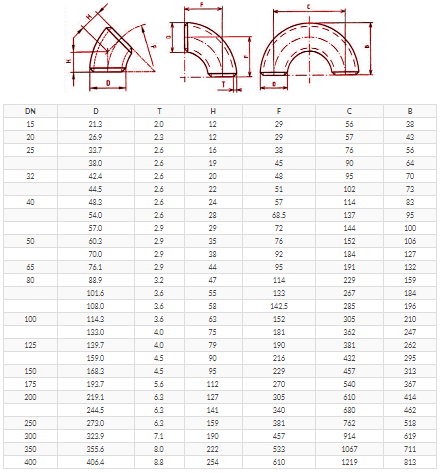

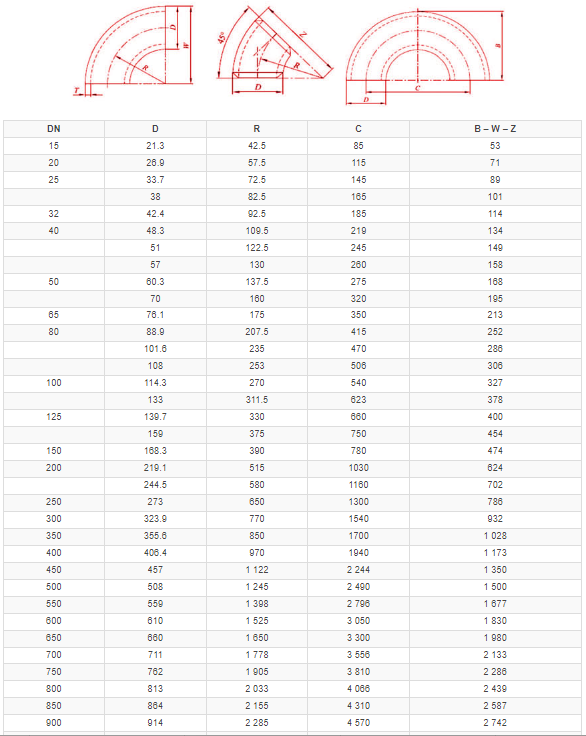

ASME B16.9 5D PIPE BEND DIMENSIONS, 5D PIPE BEND DIMENSIONS

![]()

1D/ 1.5D PIPE BEND WEIGHT CHART

ANSI B16.9 3D PIPE BEND WEIGHT

5D PIPE BEND WEIGHT CHART

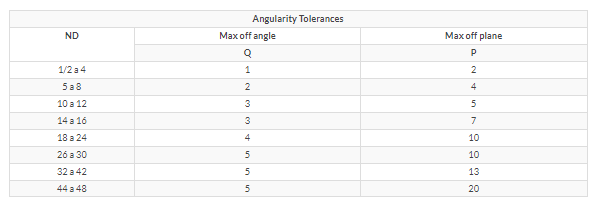

DIMENSIONAL TOLERANCES OF ASME B16.9 1D PIPE BEND , LONG RADIUS 1.5D PIPE BEND, 3D PIPE BEND, 5D PIPE BEND

1D / 1.5D / 3D / 5D PIPE BEND SPECIFICATIONS

Manufacturing standard: AISI B16.49, MSS-SP-75

Material: Carbon steel, Alloy steel, Stainless steel

Material standards: API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 & SOUR; ASTM A234 WPB, WPC, WP1, WP5, WP9, WP11, WP22, WP91; ASTM A403 304/304L, 316/316L.

Outer Diameters: 1/2'' to 60''. DN15 to DN1500

Radius range: R=2D, 2.5D, 3D bend, 5D bend, 6D, 8D bend

Degree range: 45 degree, 60 degree, 90 degree and customized.

Wall thickness: SCH 10, SCH 40, SCH80

Coatings: Black paint, galvanized, epoxy coated, 3PE, FBE

MESSAGE